RRPO 2013 project

Construction of a pilot reactor for the drying and disinfection of municipal and/or industrial sludge from treatment plants

Legal basis and starting points

In accordance with applicable legislation of the Republic of Slovenia, the disposal of untreated sludge from municipal treatment plants to landfill sites for non-hazardous waste is no longer permitted as of 15 July 2009. The sludge market is increasing from year to year due to stricter environmental protection legislation, increased growth and population density, and the consequent increase in the number of water treatment plants. It was therefore necessary to develop technologies and processes that enable the use of non-hazardous wastes in industry or agriculture.

The starting points of the research and development project for the drying of municipal and/or industrial sludge from waste water treatment plants were determined with the assumption that sludge is a raw material or energy source which can be useful as a fertiliser, raw material for composting, construction material, soil or alternative fuel, if properly treated. Drying is among the most commonly used processes of preparation for further or final use.

Sludge treatment capacities in the Republic of Slovenia are not sufficient to meet demand, thus the export share is increasing.

Key project objective:

to find a technically and economically effective solution for the drying and disinfection of industrial and municipal sludge, and thus prepare it for use as an energy source, and for other uses.

Project activities

The project is based on a previous study of known technologies for the drying and disinfection of sludge from the legislative, social, economic, energy and environmental protection standpoints.

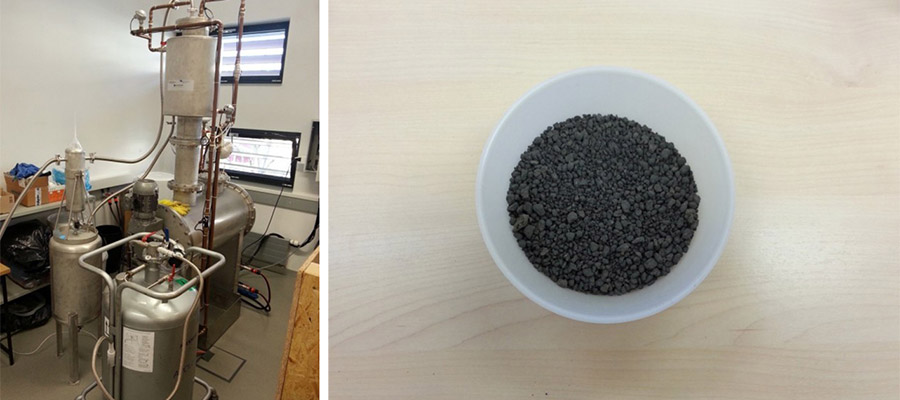

Based on the experiments in the pilot vacuum device, the possibilities of sludge disinfection under vacuum and the upgrade of disinfection by means of physical-chemical and microbiological testing were researched. In this way, we were looking for the most effective technology for the disinfection of sludge with various properties.

The experimental part of the project provided the basis for determining the technological parameters of drying and disinfection of sludge with various physical-chemical and biological characteristics, namely for different users depending on their energy, economic and environmental viability.

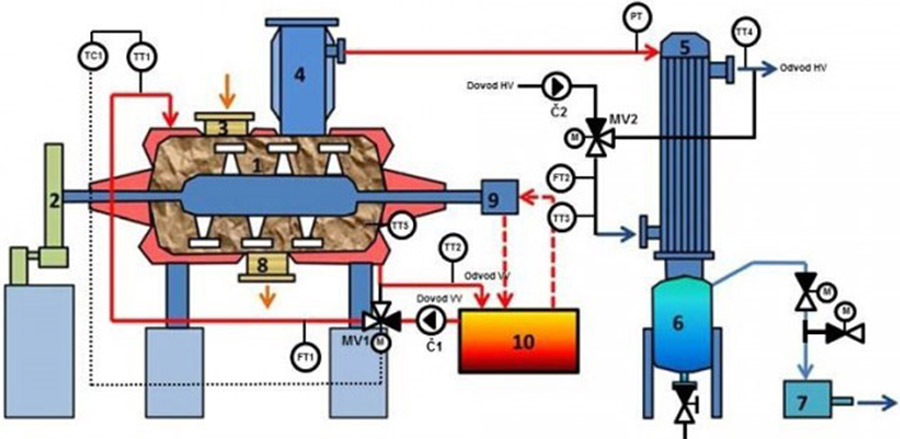

Developed mechanical equipment

The following mechanical equipment was developed in the scope of the project:

- reactor mixer for the mixing of sludge mass with various characteristics,

- heat exchanger with a low-temperature regime < 40°C,

- electronics with temperature, pressure and flow sensors to control the process of drying and disinfection,

- pilot vacuum device for drying and disinfection.

Application of results

The results of the experimental part of the project showed that the sludge drying technology under vacuum can be applied to both stabilised and non-stabilised sludge. We developed the concept of a hypobaric drying chamber, which allows the drying of industrial and municipal sludge to 10% dry mass or less, and prepared the guidelines for the production of an industrial device for the drying and disinfection of municipal and/or industrial sludge with a capacity of 100 tonnes/day.

Target group

The project results are interesting for the producers, collectors, processors and users of industrial and municipal sludge.

Environmental impact

Treatment of sludge is a complex process, whereby both, the microbiological and chemical aspects, have to be observed in order to protect people and the environment from the risks of pathogens, the spread of dangerous infections and diseases to humans, animals and plants.

By drying the sludge its volume is reduced, which has the positive effect of reducing the number of necessary transports and the consequent negative impact of transport on the environment. At the same time, the calorific value of the sludge increases, the sludge becomes hygiene-stabilised (no pathogens) and its structure improves, thereby increasing the possibilities of its use in the energy industry or agriculture.

Co-incineration of waste sludge is an important substitution for primary fossil fuels.

Since the drying process is very energy-consuming, it makes sense to use the "waste" heat energy with the aim of reducing the use of fossil fuels.

Planned further development

The technology for drying sludge and/or residual digestate from waste water treatment plants with low-temperature regime of the heating medium and the sub-pressure of the drying area gives the possibility of an energy-efficient device, especially if we have at our disposal a low-temperature medium as the heat for evaporating the water from the sludge (for example, waste heat from the cooling water of thermal plants). The developed system allows the design and construction of a modular industrial device with the capacity of approx. 25 tonnes per unit, depending on the quantity of sludge and/or digestate generated at the area concerned.

Further development of sludge drying under vacuum allows us to achieve energy self-sufficient operation of the waste water treatment plant, and in some cases, even energy peaks that could be used as heat or electrical energy, depending on the energy obtained in the process of steam condensation and the available waste heat, which could be used as a heating medium in the drying process.

Surovina research team in cooperation with the University of Maribor

The project was carried out within the framework of cooperation between the research team of Surovina d.o.o. and the University of Maribor, and was co-financed by the Republic of Slovenia and the European Union, provided by the European Regional Development Fund. The funds were obtained through a public tender for promoting research and development projects in problematic areas with high unemployment from 2013 to 2015 - RRPO 2013. Presentation of project results

1. Ljubljana Exhibition and Convention Centre, Nature-Health Fair 2014 (approx. 22,000 visitors), 13-16 November 2014. Lecture title: Presentation of a pilot reactor for the drying and disinfection of municipal and/or industrial sludge from treatment plants.

2. Presentation of interim results of the research project by partners Surovina and the University of Maribor: FERI, FNM and FS, FERI, 4 December 2014.

3. Ptuj, ZRS Bistra Ptuj, 9-10 April 2015 (lecture at the conference and publication of an article in the proceedings): Sludge drying in a vacuum reactor.

4. Conference in Maribor: Automation in Industry and Economy (9 ; 2015 ; Maribor), Proceedings of the 9th Conference on Automation in Industry and Economy, 9 and 10 April 2015, Lecture title: Advanced operation of the pilot device for the drying of unstabilised sludge from treatment plants

Documents:

1 Ljubljana Exhibition and Convention Centre - Presentation of pilot reactor (PDF / 967.36 kB)

2 FERI - Presentation of interim results (PDF / 3.22 MB)

3 Bistra Ptuj - Sludge drying in vacuum reactor - Article (PDF / 374.99 kB)

3 Bistra Ptuj - Sludge drying in vacuum reactor - Presentation (PDF / 2.93 MB)

Paper aiq15 (PDF / 638,32 kB)

Presentation of AIG15 (PDF / 1.09 MB)